Our service offering

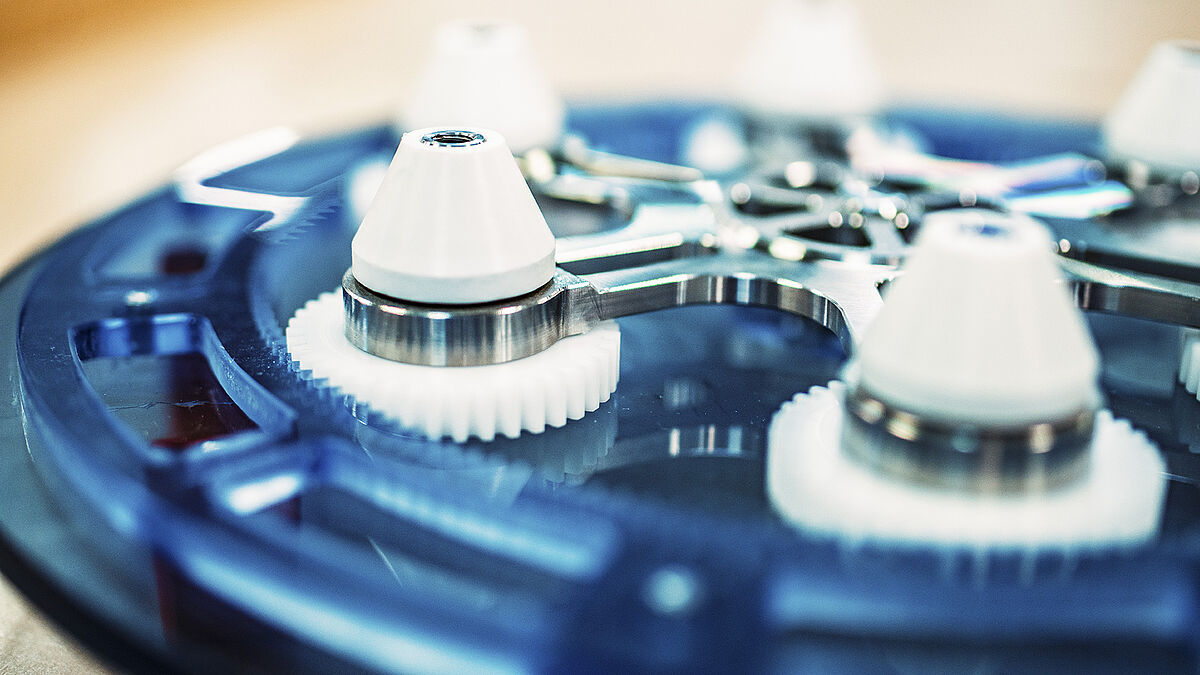

With our over ten years’ experience in plastics processing to German quality standards, we can support you with the manufacture of plastic assemblies and the installation of complex assemblies. The necessary components and individual parts can be produced at our plant if required. Our machining services include milling, turning, sawing, drilling, welding, and the installation of assemblies.

Our highly qualified employees guarantee consistently high-quality products. Our state-of-the-art fleet of machinery enables us to minimize production times while also meeting the most stringent requirements in terms of methods and machining techniques.